Ons salesteam helpt je graag!

Divisies

Specialist voor al je elektrotechnische installaties.

Dit is Moekotte voor jou

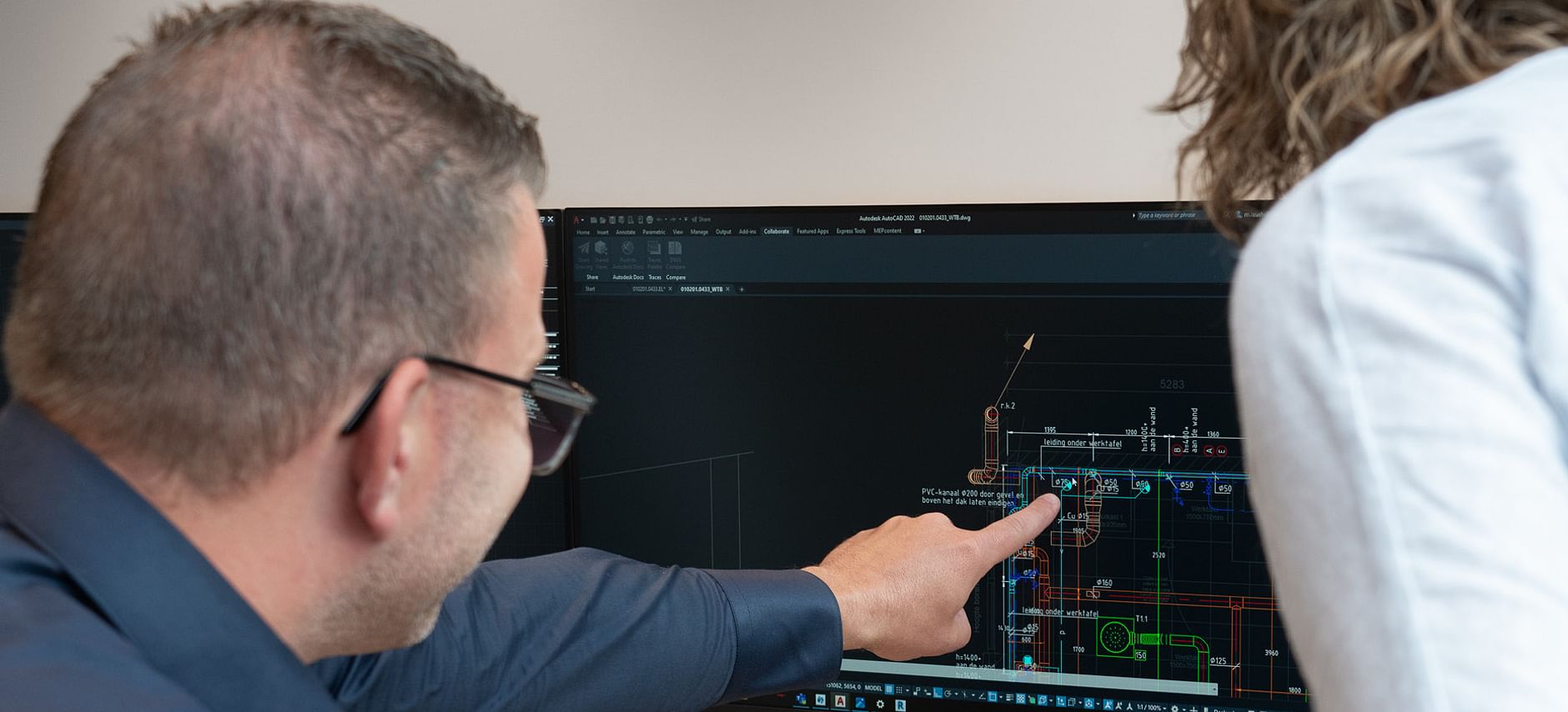

Meer over MoekotteEngineer

Meedenken en ontwikkelen van soft- en hardware rondom industriële installaties – daar beginnen we mee. Met als resultaat? Slimme techniek die efficiënter werkt en kosten bespaart.

Install

Regeltechniek, mechanische componenten, verwarming, koeling, waterbehandeling – wij zetten alles voor je installaties zó in, dat je mensen en machines hier het meeste uithalen.

Maintain

Je installatie laten we op elk moment werken op het niveau dat je wilt. Van gepland onderhoud en resultaatgerichte service tot onderhoud van gebouwen.